Refractory Blocks

Refractory Blocks Specification

- Water Absorption

- 8%

- Drying Shrinkage

- 0.2%

- Porosity (%)

- 17 24%

- Compressive Strength

- 45 MPa

- Dimension (L*W*H)

- As per requirement, e.g., 230 x 115 x 75 mm

- Working Life

- Long, Suitable for Industrial Furnaces

- Bricks Type

- Refractory Block

- Material

- High Alumina Refractory

- Type

- Heat Insulation Refractory

- Color

- Light Brown / Beige

- Size

- 230 x 115 x 75 mm (standard); Custom sizes available

- Shape

- Rectangular / Trapezoidal / Custom

- Porosity

- Low to Medium

- Thickness

- 50 mm 150 mm

- Technics

- Sintered

- Feature

- Excellent Thermal Shock Resistance, High Strength, Corrosion Resistant

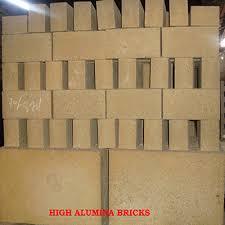

About Refractory Blocks

Buy from us customized REFRACTORY BLOCKS for high temperature furnaces, industrial ovens, and rotary kilns to enhance physical strength of the walls as well as prevent heat leakages. The offered heavy duty cementitious block is made up of raw materials added with alumina oxide and iron oxide in proportionate amounts that result in high physical strength and excellent chemical resistance. It is available in various sizes as per the order placed by our customers. The offered REFRACTORY BLOCKS can be delivered to our clients as per the order placed by them with an assurance of fast and safe delivery at a low price.

Precision Heat Insulation for Industrial Applications

Our high alumina refractory blocks are designed for efficient thermal insulation in various high-temperature setups such as furnaces, kilns, and fireboxes. Their robust composition ensures minimal heat loss, optimal performance, and greater safety in industrial processes requiring sustained exposure to heat.

Customized Solutions and Versatile Shapes

Available in standard dimensions of 230 x 115 x 75 mm and thicknesses between 50 mm and 150 mm, our blocks can be manufactured in rectangular, trapezoidal, or custom shapes. This adaptability allows seamless integration into your unique designs, ensuring a precise and reliable fit for any project.

Outstanding Durability and Performance

Boasting high compressive strength ( 45 MPa), low water absorption, and excellent abrasion resistance, these refractory blocks deliver long service life even under harsh operating conditions. The sintered manufacturing process enhances their resilience to thermal shock and corrosion, sustaining performance over years of rigorous use.

FAQs of Refractory Blocks:

Q: How are high alumina refractory blocks used in industrial furnaces and kilns?

A: These blocks are primarily installed as linings for furnaces, kilns, fireboxes, and fireplaces to provide superior thermal insulation and protect structural components from intense heat and wear. Their robust properties enable them to endure heavy mechanical and thermal stresses typical in high-temperature processing environments.Q: What benefits do refractory blocks with high bulk density and low thermal conductivity offer?

A: Blocks with bulk density between 2.22.6 g/cm and thermal conductivity of 1.3 W/(mK) ensure enhanced heat insulation, minimizing heat transfer while maintaining structural integrity. This results in improved energy efficiency, reduced fuel consumption, and safer operation within industrial facilities.Q: When should I opt for custom-shaped refractory blocks over standard sizes?

A: Custom-shaped blocks are ideal when your furnace or application requires specific geometries or dimensions to achieve optimal fit or solve unique engineering challenges. Our production flexibility ensures that we can meet you specific requirements, whether for repairs, retrofits, or new installations.Q: Where can I source these refractory blocks in India?

A: You can procure these high alumina refractory blocks from recognized dealers, distributors, manufacturers, suppliers, traders, wholesalers, and service providers across India. Whether you need bulk orders or specialized supplies, we cater to diverse industry needs nationwide.Q: What is the manufacturing process for these refractory blocks?

A: The blocks are made using a sintered process, where high alumina materials are carefully blended, shaped, and fired at high temperatures. This technique ensures consistent density, low porosity, and outstanding durability, making the bricks highly resistant to thermal and mechanical stresses.Q: How does high abrasion resistance affect the working life of refractory blocks?

A: High abrasion resistance significantly enhances the longevity of refractory blocks, as they can withstand mechanical wear from loading, thermal cycling, and corrosive agents, reducing the frequency of replacements and downtime in industrial operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Furnace Refractory Category

FURNACE REFRACTORY

Shape : Rectangular

Type : Other, Furnace Refractory

Size : 9 x 4.5 x 3 inches

Thickness : 75 mm

Material : Other, High Alumina, Fire Clay

Feature : Other, High thermal resistance, Abrasion resistant

REFRACTORY BRICKS

Shape : 9" x 4.5" x 3"

Type : Engineering Bricks

Size : 9" x 4.5" x 3"

Thickness : 76.2 Millimeter (mm)

Material : Clay

Feature : High Strength, Fire Brick, Heatinsulation, Fireretardant

We mainly deal in Chandigarh, Delhi, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Uttar Pradesh, Punjab, Rajasthan, Uttarakhand etc.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS