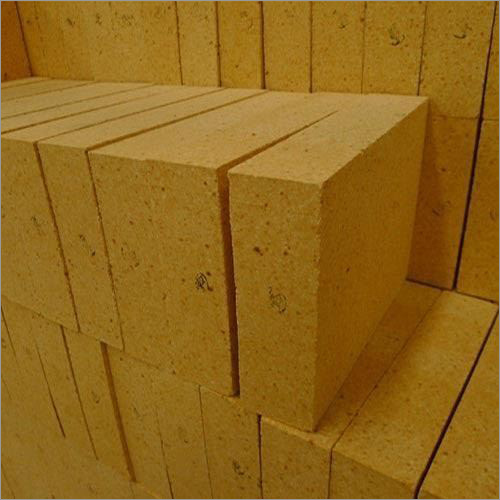

THERMAX BRICKS

THERMAX BRICKS Specification

- Material

- Fireclay, Alumina

- Shape

- Rectangular (Brick Shape)

- AI2O3(%)

- 38.90%

- Fe2O3 (%)

- 2.05%

- Refractoriness

- 1790C

- Characteristics

- Highly insulating, lightweight, low thermal conductivity

- Color

- Light Yellow

About THERMAX BRICKS

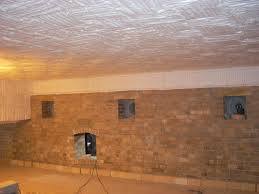

We are offering premium grade THERMAX BRICKS in various customizable sizes as per the order placed by our customers and applications areas. It is made up by using advanced production methods that give high dimensional accuracy and high uniformity. It is in high demand for the construction of linings within furnaces, chimneys, coking plants, power plant boilers, and industrial ovens to add extra strength and rigidity to bear extreme temperatures which lead to longer service life. The high environment friendliness of the offered brick makes it highly demanding among our customers. Get THERMAX BRICKS in bulk with an assurance of fast and safe delivery.

Superior Insulation for Industrial Applications

THERMAX BRICKS are designed for maximum insulation in high-temperature environments, such as furnace linings and kiln insulation. With their lightweight structure and low thermal conductivity, they significantly reduce heat loss, ensuring efficient energy utilization. This makes them an ideal choice for various industries requiring reliable thermal management, including power plants, manufacturing units, and metal treatment facilities.

Compliance and Reliability

Manufactured according to IS:2042-1972 standards, THERMAX BRICKS guarantee consistency in quality and performance. Their impressive cold crushing strength and refractoriness offer robust protection against mechanical and thermal stress. These qualities also support prolonged service life and minimal maintenance for major industrial installations.

FAQs of THERMAX BRICKS:

Q: How are THERMAX BRICKS used in industrial furnace lining or kiln insulation?

A: THERMAX BRICKS are installed as the primary lining material for furnaces, kilns, boilers, and heat treatment chambers. Their high insulation properties and thermal stability help maintain optimal temperature conditions, improving the efficiency and longevity of these installations.Q: What benefit does the low thermal conductivity of THERMAX BRICKS offer?

A: The low thermal conductivity (0.27-0.31 W/mK) greatly reduces heat transfer, enhancing energy conservation in industrial applications. This minimizes heat loss and helps regulate internal temperatures, ensuring cost-effective operation and improved safety.Q: When should THERMAX BRICKS be considered over other insulating materials?

A: THERMAX BRICKS are ideal when high-temperature resistance up to 1250C, lightweight construction, and superior insulation are required, particularly in furnace, kiln, and boiler applications where conventional bricks might fail to deliver efficient performance.Q: Where can THERMAX BRICKS be sourced in India?

A: THERMAX BRICKS are available through dealers, distributors, manufacturers, suppliers, retailers, and traders across India. Several wholesalers and service providers also offer support for selection, delivery, and installation as per your industrial requirements.Q: What is the manufacturing process for THERMAX BRICKS and how does it ensure quality?

A: THERMAX BRICKS are manufactured from fireclay and high-purity alumina using advanced techniques to control porosity and strength. Each batch is tested to meet IS:2042-1972 compliance, ensuring consistent density, thermal properties, and durability for industrial use.Q: What are the advantages of the high apparent porosity in THERMAX BRICKS?

A: High apparent porosity (45-55%) allows for effective thermal insulation, reducing heat transfer and supporting stable temperature retention within industrial furnaces and kilns, thus optimizing energy usage and process efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Thermax Refractory Bricks Category

Thermax Refractory Brick

Material : Other, High Alumina

Color : Light Brown

AI2O3(%) : 70%

Refractoriness : 1750C

Characteristics : High thermal stability, corrosion resistance, abrasion resistance

Fe2O3 (%) : 2.5%

Thermax Boiler

Material : Other, Mild Steel

Color : Blue

AI2O3(%) : 21%

Refractoriness : High

Characteristics : Long service life, High efficiency

Fe2O3 (%) : 4%

THERMAX BOILER LINING

Material : Other, Highgrade Refractory Castable

Color : Grey

AI2O3(%) : 45

Refractoriness : 1700C

Characteristics : High thermal shock resistance, excellent insulation, wear resistance

Fe2O3 (%) : 1.2

We mainly deal in Chandigarh, Delhi, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Uttar Pradesh, Punjab, Rajasthan, Uttarakhand etc.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS