Thermax Boiler

Thermax Boiler Specification

- Material

- Mild Steel

- Shape

- Horizontal

- AI2O3(%)

- 21%

- Fe2O3 (%)

- 4%

- Refractoriness

- High

- Characteristics

- Long service life, High efficiency

- Color

- Blue

About Thermax Boiler

Thermax Boiler

We provide this Thermax Boiler Work to our prestigious clients at cost effective prices within a scheduled time frame. Our provided service is highly admired in paper & pulp, sugar processing, food & beverage, power generation, food processing and chemical industries. After manufacturing procedure, boilers are perfectly fabricated with the use advanced machines to ensure a long lasting seamless finish. Our objective to render this service is to provide durable, reliable, leakage proof, and fuel efficient boilers. Moreover, the entire process of thermax boiler is carried out in a sequential manner to attain utmost satisfaction.

We provide this Thermax Boiler Work to our prestigious clients at cost effective prices within a scheduled time frame. Our provided service is highly admired in paper & pulp, sugar processing, food & beverage, power generation, food processing and chemical industries. After manufacturing procedure, boilers are perfectly fabricated with the use advanced machines to ensure a long lasting seamless finish. Our objective to render this service is to provide durable, reliable, leakage proof, and fuel efficient boilers. Moreover, the entire process of thermax boiler is carried out in a sequential manner to attain utmost satisfaction.

High Efficiency and Automation

This Thermax Smoke Tube Boiler ensures optimal energy use with up to 89% efficiency and fully automatic controls. Its horizontal design promotes even heat distribution, reducing fuel consumption. Automation ensures consistent performance and minimal manual intervention, making operations smoother and more reliable for industrial demands.

Durable Design for Industrial Needs

Constructed from mild steel with a robust refractory lining (Fe2O3 at 4% and AI2O3 at 21%), this boiler withstands high temperatures and pressure (10.54 kg/cm2). Its long service life and high refractoriness make it ideal for demanding environments, from manufacturing units to large-scale production plants.

FAQs of Thermax Boiler:

Q: How does the Thermax Smoke Tube Boiler achieve high efficiency in operation?

A: The Thermax Smoke Tube Boiler maximizes fuel-to-steam conversion through advanced combustion technology and a well-designed heat exchange area, which helps maintain efficiency up to 89%. Automated controls further optimize the process, ensuring minimal energy wastage.Q: What is the recommended process for installing this boiler in an industrial facility?

A: Professional installation is essential for safety and efficiency. It involves site assessment, proper foundation placement, connecting oil or gas fuel lines, electrical integration (415 V), and alignment with the existing steam distribution system. A certified technician should perform the commissioning.Q: When should regular maintenance be performed on the Smoke Tube Boiler?

A: Routine maintenance is recommended every six months or as per the manufacturers guidelines. Regular inspections help prevent scale formation, check refractory material integrity, and ensure all automatic controls are functioning optimally.Q: Where can the Thermax Smoke Tube Boiler be sourced in India?

A: This boiler is available through authorized Thermax dealers, distributors, suppliers, and wholesalers across India. Purchase can be arranged directly from manufacturers, retailers, or dedicated service providers for industrial boilers.Q: What are the primary usage applications for this boiler model?

A: The Thermax Smoke Tube Boiler excels in supplying reliable steam for chemical, food processing, textile, pharmaceuticals, and manufacturing sectors. Its robust build and automation make it suitable for both medium and large-scale industries requiring consistent steam generation.Q: What benefits does this boiler offer to distributors and end users?

A: Distributors and end users benefit from its long service life, high thermal efficiency, and automatic operation, reducing downtime and maintenance costs. Its high refractoriness ensures excellent performance even in rigorous industrial settings, providing value and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Thermax Refractory Bricks Category

THERMAX BOILER LINING

Refractoriness : 1700C

Material : Other, Highgrade Refractory Castable

Shape : Other, Rectangular Blocks

AI2O3(%) : 45

Characteristics : High thermal shock resistance, excellent insulation, wear resistance

Fe2O3 (%) : 1.2

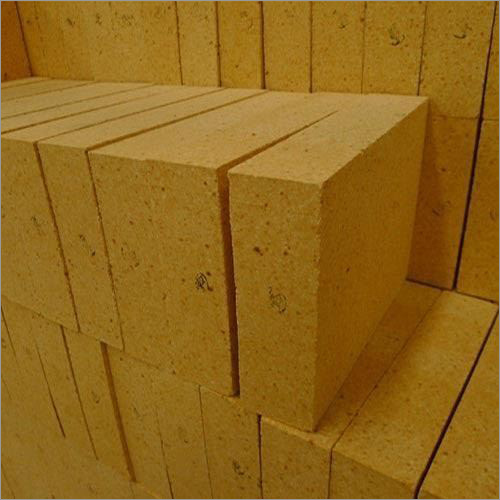

THERMAX BRICKS

Refractoriness : 1790C

Material : Other, Fireclay, Alumina

Shape : Other, Rectangular (Brick Shape)

AI2O3(%) : 38.90%

Characteristics : Highly insulating, lightweight, low thermal conductivity

Fe2O3 (%) : 2.05%

Thermax Refractory Brick

Refractoriness : 1750C

Material : Other, High Alumina

Shape : Other, Rectangular

AI2O3(%) : 70%

Characteristics : High thermal stability, corrosion resistance, abrasion resistance

Fe2O3 (%) : 2.5%

We mainly deal in Chandigarh, Delhi, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Uttar Pradesh, Punjab, Rajasthan, Uttarakhand etc.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS