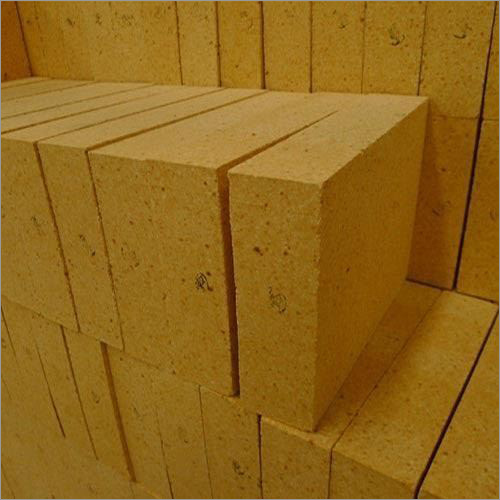

Thermax Refractory Brick

Thermax Refractory Brick Specification

- Material

- High Alumina

- Shape

- Rectangular

- AI2O3(%)

- 70%

- Fe2O3 (%)

- 2.5%

- Refractoriness

- 1750C

- Characteristics

- High thermal stability, corrosion resistance, abrasion resistance

- Color

- Light Brown

- Length

- 230 mm

- Bulk Density

- 2.3 g/cm³

- Usage/Application

- High-temperature furnaces, kilns, and incinerators

- Cold Crushing Strength

- 350 kg/cm²

- Resistance to Thermal Shock

- Excellent

- Apparent Porosity

- 23%

- Thickness

- 80 mm

- Width

- 114 mm

About Thermax Refractory Brick

Thermax Refractory Brick

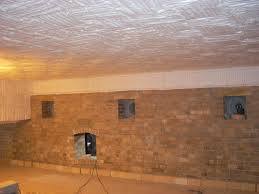

This Thermax Refractory Brick is manufactured using the best quality raw materials and sophisticated machines by a team of skilled professionals. Our offered brick is chemically and physically quite stable at high temperature. Owing to its ability to withstand heat combination exposure continuously, this brick is used in lining furnaces, fireboxes, fireplaces, and kilns. Along with this, the provided brick can be availed from us in various designs and dimensions i.e. length, width, and height.

Key points:

This Thermax Refractory Brick is manufactured using the best quality raw materials and sophisticated machines by a team of skilled professionals. Our offered brick is chemically and physically quite stable at high temperature. Owing to its ability to withstand heat combination exposure continuously, this brick is used in lining furnaces, fireboxes, fireplaces, and kilns. Along with this, the provided brick can be availed from us in various designs and dimensions i.e. length, width, and height.

Key points:

- Admired for low thermal conductivity to provide greater energy efficiency

- Suitable for extreme mechanical, chemical and thermal stresses applications

- Each dimension is perfectly finished in accurate size

Engineered for Extreme Thermal Conditions

Thermax Refractory Bricks are meticulously crafted using high alumina material to perform reliably under very high temperatures. Their excellent resistance to thermal shock and corrosive atmospheres makes them a preferred choice for furnaces, kilns, and incinerators, guaranteeing longevity and consistent performance even in the most challenging environments.

Advanced Material Composition for Superior Performance

With 70% Al2O3 and only 2.5% Fe2O3, these bricks offer impressive refractoriness and maintain their integrity up to 1750C. The design incorporates high thermal stability and low apparent porosity (23%), resulting in reduced heat loss and enhanced operational efficiency for industrial applications.

FAQs of Thermax Refractory Brick:

Q: How should Thermax Refractory Bricks be installed in high-temperature equipment?

A: Thermax Refractory Bricks are usually installed by arranging them in specific patterns within the lining of furnaces, kilns, or incinerators. Proper alignment and use of compatible refractory mortar are crucial for ensuring thermal efficiency, structural stability, and protection against heat-induced damage.Q: What benefits do Thermax Refractory Bricks provide in industrial furnaces and kilns?

A: These bricks offer high thermal stability, corrosion and abrasion resistance, and excellent thermal shock resistance, resulting in extended equipment life, improved energy efficiency, and minimized downtime due to maintenance or repairs.Q: When should high alumina refractory bricks such as Thermax be selected over other types?

A: High alumina bricks like Thermax are ideal for situations requiring high refractoriness, up to 1750C, and environments exposed to severe abrasion, corrosion, or thermal cycling, such as steel plants, cement kilns, and incineration chambers.Q: Where are Thermax Refractory Bricks most commonly used?

A: These bricks are widely utilized in high-temperature unitsincluding furnaces, kilns, and incineratorsacross industries such as metallurgy, glass, and cement manufacturing throughout India.Q: What is the process involved in manufacturing Thermax Refractory Bricks?

A: The bricks are produced by blending high-grade alumina and select materials, molding them into precise rectangular shapes, and firing at high temperatures. This process ensures optimal density, low porosity, and consistent structural properties.Q: How does the bricks bulk density and porosity contribute to its performance?

A: A bulk density of 2.3 g/cm and an apparent porosity of 23% enable the brick to resist aggressive thermal and chemical environments while minimizing heat absorption, ensuring higher durability and operational stability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Thermax Refractory Bricks Category

Thermax Boiler

Refractoriness : High

AI2O3(%) : 21%

Characteristics : Long service life, High efficiency

Fe2O3 (%) : 4%

Shape : Other, Horizontal

Material : Other, Mild Steel

THERMAX BRICKS

Refractoriness : 1790C

AI2O3(%) : 38.90%

Characteristics : Highly insulating, lightweight, low thermal conductivity

Fe2O3 (%) : 2.05%

Shape : Other, Rectangular (Brick Shape)

Material : Other, Fireclay, Alumina

THERMAX BOILER LINING

Refractoriness : 1700C

AI2O3(%) : 45

Characteristics : High thermal shock resistance, excellent insulation, wear resistance

Fe2O3 (%) : 1.2

Shape : Other, Rectangular Blocks

Material : Other, Highgrade Refractory Castable

We mainly deal in Chandigarh, Delhi, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Uttar Pradesh, Punjab, Rajasthan, Uttarakhand etc.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS