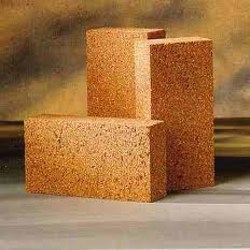

Refractory Fire Bricks

Refractory Fire Bricks Specification

- Material

- Clay

- Shape

- Brick

- AI2O3(%)

- 35% to 40%

- Fe2O3 (%)

- Less than 1.5%

- Refractoriness

- Above 1700C

- Characteristics

- High durability, thermal stability, chemical resistance

- Color

- Brown

- Size

- 230mm x 114mm x 65mm

- Thermal Conductivity

- Low

- Water Absorption (%)

- 13-15%

- Cold Crushing Strength (kg/cm)

- 350 minimum

- Apparent Porosity (%)

- 18-20%

- Bulk Density (gm/cm)

- 1.85 2.05

About Refractory Fire Bricks

REFRACTORY FIRE BRICKS

The offered Refractory Fire Bricks are made available by us for use in the various construction and other applications. The offered bricks are very effective and strong. A fire brick, firebrick, or refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces. They are primarily built to resist excessive temperatures, usually have to decrease thermal conductivity for higher power efficiency. Fire clay is used for making this type of bricks. The offered bricks are very effective and are easy to handle. The Refractory Fire Brick is made available by us for construction.

Exceptional Heat Resistance and Durability

Refractory Fire Bricks are engineered to withstand extreme temperatures, offering refractoriness above 1700C. Their specialized compositionfeaturing high Al2O3 and low Fe2O3ensures resilience against harsh thermal cycles and chemical attacks, making them a preferred choice for industrial furnaces and kilns.

Consistent Quality with Advanced Composition

Manufactured using high-grade clay, these bricks maintain a balanced bulk density (1.852.05 gm/cm) and optimal porosity (1820%), ensuring uniform performance. Their controlled water absorption minimizes damage during frequent heating and cooling, while low thermal conductivity enhances energy efficiency in operational settings.

Versatility and Broad Market Availability

These fire bricks are widely supplied, traded, and distributed through established networks across India. Dealers, wholesalers, and service providers cater to diverse industries, enabling easy access for both large-scale manufacturers and focused project requirements.

FAQs of Refractory Fire Bricks:

Q: How are these refractory fire bricks manufactured to ensure high durability and thermal stability?

A: The fire bricks are manufactured from high-quality clay with 35%40% Al2O3 and less than 1.5% Fe2O3, ensuring both durability and thermal stability. They undergo a high-temperature firing process that gives them a dense structure, low porosity, and robust mechanical strength.Q: What industrial applications are best suited for these clay fire bricks?

A: These bricks are ideal for lining furnaces, kilns, incinerators, boilers, and other equipment exposed to intense heat. Their chemical resistance and ability to endure temperatures above 1700C make them suitable for steel, glass, cement, and ceramic industries.Q: When should I replace refractory bricks in my machinery or furnaces?

A: Replacement is needed when signs of wear such as cracks, spalling, or excessive deformation are observed, or after prolonged operational periods where performance declines. Regular inspection helps determine the right moment for replacement to maintain equipment efficiency.Q: Where can these refractory fire bricks be sourced in India?

A: You can source these bricks from reputable dealers, distributors, manufacturers, suppliers, and wholesalers across India. Many retailers and service providers offer countrywide distribution and technical support for industrial buyers.Q: What process ensures the bricks resistance to chemicals and high temperatures?

A: A carefully controlled raw material selection and high-temperature firing process guarantee chemical resistance and stability at elevated temperatures. The precise combination of alumina and controlled porosity ensures reliable performance even in aggressive environments.Q: How does low thermal conductivity benefit operational safety and efficiency?

A: Low thermal conductivity minimizes heat loss through the brick lining, increasing energy efficiency and helping maintain a safer, cooler exterior surface for operators and equipment surroundings.Q: What are the advantages of the bricks specific size and uniformity for installation?

A: The standardized size (230mm x 114mm x 65mm) and brick shape facilitate easy handling, precise installation, and a snug fit, resulting in stable, continuous walls or linings that limit gaps and potential hot spots.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Refractory Material Category

Refractory Material

Fe2O3 (%) : 24%

Characteristics : High temperature resistance, superior thermal stability

AI2O3(%) : 4045%

Material : Other, Refractory Material

Color : Brown

Refractoriness : 1790C

REFRACTORY SHAPES AND GOODS

Fe2O3 (%) : <1.5%

Characteristics : Excellent thermal stability, high mechanical strength, corrosion resistance

AI2O3(%) : 3060%

Material : Other, Highquality refractory ceramics

Color : Light brown/cream

Refractoriness : >1700C

We mainly deal in Chandigarh, Delhi, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Uttar Pradesh, Punjab, Rajasthan, Uttarakhand etc.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS