Refractory Material

Refractory Material Specification

- Material

- Refractory Material

- Shape

- Granule

- AI2O3(%)

- 40-45%

- Fe2O3 (%)

- 2-4%

- Refractoriness

- 1790C

- Characteristics

- High temperature resistance, superior thermal stability

- Color

- Brown

- Thermal Conductivity

- 1.2 W/mK at 1000C

- Cold Crushing Strength

- 350 kg/cm

- Usage

- Lining of furnaces, kilns, incinerators

- Water Absorption

- 2%

- Bulk Density

- 2.3 to 2.5 g/cm

- Packaging

- Standard export bags or as required

- Apparent Porosity

- 22%

About Refractory Material

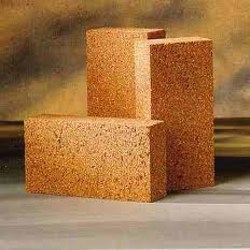

REFRACTORY MATERIAL

The offered REFRACTORY MATERIAL ismade available by us for making the various items like bricks and others for use in the various commercial and industrial applications. The offered material is very effective and has a high resistance to excess temperature. It is a material that is resistant to decomposition by heat, pressure, or chemical attack, and retains strength and form at high temperatures. Refractories are inorganic, nonmetallic, porous, and heterogeneous. It is any material that has an unusually high melting point and that maintains its structural properties at very high temperatures. The REFRACTORY MATERIAL is very durable and safe.

Reliable Thermal Performance

This refractory material is specifically designed to withstand continuous exposure to high temperatures and thermal cycling, making it ideal for lining furnaces, kilns, and incinerators. Its robust composition ensures minimal thermal conductivity at elevated temperatures, substantially enhancing energy efficiency and structural integrity.

Engineered for Industrial Applications

With superior cold crushing strength and low water absorption, this material resists physical and chemical degradation in harsh environments. Its controlled porosity and excellent refractoriness are tailored for demanding industrial uses, offering long-lasting protection and consistent performance in various thermal systems.

FAQs of Refractory Material:

Q: How should the refractory material be installed for furnace or kiln lining?

A: Installation involves preparing the surface, applying the granule-shaped material in specified layers, and compacting it to achieve optimal density and integrity. Expert technicians or installation services are recommended to ensure proper thermal stability and longevity.Q: What benefits does the materials thermal conductivity offer at 1000C?

A: With a thermal conductivity of 1.2 W/mK at 1000C, the material retains heat efficiently within the system, minimizing energy loss and improving the operational efficiency and safety of furnaces and kilns.Q: When is this refractory material most suitable for industrial use?

A: This product is ideal for applications requiring high temperature resistance and durability, such as during the initial lining or refurbishment of furnaces, kilns, and incinerators in steel, ceramic, or waste management industries.Q: Where can the refractory material be sourced in India?

A: The material is available nationwide through a network of dealers, distributors, manufacturers, retailers, suppliers, and wholesalers. Custom packaging and supply options can be arranged based on project or export requirements.Q: What process is used to manufacture this refractory material?

A: The production involves precise mixing of raw materials with a composition of 4045% Al2O3 and 24% Fe2O3, forming granules that are subsequently heat-treated to optimize density, porosity, and thermal resistance.Q: How does the materials apparent porosity influence its performance?

A: Apparent porosity 22% ensures excellent resistance to slag and corrosive gases, minimizing permeation and prolonging the protective lifespan of furnace or kiln linings.Q: What advantages does low water absorption provide for industrial linings?

A: A water absorption rate of 2% minimizes the risk of chemical attack and spalling during operation, contributing to the materials structural integrity and enhancing the overall safety and durability of lined equipment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Refractory Material Category

REFRACTORY SHAPES AND GOODS

Shape : Other, Various shapes and customized forms

Material : Other, Highquality refractory ceramics

AI2O3(%) : 3060%

Characteristics : Excellent thermal stability, high mechanical strength, corrosion resistance

Refractoriness : >1700C

Fe2O3 (%) : <1.5%

Refractory Fire Bricks

Shape : Brick

Material : Clay

AI2O3(%) : 35% to 40%

Characteristics : High durability, thermal stability, chemical resistance

Refractoriness : Above 1700C

Fe2O3 (%) : Less than 1.5%

We mainly deal in Chandigarh, Delhi, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Uttar Pradesh, Punjab, Rajasthan, Uttarakhand etc.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS