REFRACTORY SHAPES AND GOODS

REFRACTORY SHAPES AND GOODS Specification

- Material

- High-quality refractory ceramics

- Shape

- Various shapes and customized forms

- AI2O3(%)

- 30-60%

- Fe2O3 (%)

- <1.5%

- Refractoriness

- >1700C

- Characteristics

- Excellent thermal stability, high mechanical strength, corrosion resistance

- Color

- Light brown/cream

- Dimensions

- Customizable upon request

- Bulk Density

- 2.3 2.7 g/cm

- Service Temperature

- Up to 1600C

- Usage

- Industrial high-temperature processes

- Cold Crushing Strength

- 500 900 kg/cm

- Applications

- Lining for furnaces, kilns, incinerators, and reactors

- Apparent Porosity

- 18 22%

- Thermal Expansion

- 0.6% at 1000C

- Packing

- Safe wooden pallets or as required

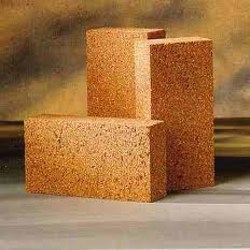

About REFRACTORY SHAPES AND GOODS

Discover our unrivaled range of Refractory Shapes and Goods, now available at a reduced price for cost-effective operations. Newly released and manufactured using champion-grade high-quality refractory ceramics, these superb products feature bulk density from 2.32.7 g/cm, cold crushing strength of 500900 kg/cm, and apparent porosity of 1822%. Customizable dimensions and various shapes cater to unique industrial requirements. With service temperatures up to 1600C and exceptional corrosion resistance, our goods are the preferred choice for dealers, distributors, manufacturers, and service providers across India.

Superior Industrial Application and Advantages

REFRACTORY SHAPES AND GOODS are specifically used for lining furnaces, kilns, incinerators, and reactors in industrial high-temperature processes. They act as a resilient barrier, ensuring excellent thermal stability, high mechanical strength, and superb resistance to corrosion. Their unrivaled composition makes them a champion solution for industries seeking durable and dependable performance, minimizing downtime and maximizing efficiency in intense heat and challenging environments.

Sample Policy and Secure Shipping

Clients can easily inquire about our sample policy, with asking price details provided on request. Each product is dispatched swiftly via secure shipping channels. We offer FOB Port delivery options, and our typical delivery time is prompt and dependable, ensuring your industrial needs are met efficiently. Safe packaging on wooden pallets or custom solutions further guarantee goods arrive in perfect condition, ready for immediate integration into your process.

Superior Industrial Application and Advantages

REFRACTORY SHAPES AND GOODS are specifically used for lining furnaces, kilns, incinerators, and reactors in industrial high-temperature processes. They act as a resilient barrier, ensuring excellent thermal stability, high mechanical strength, and superb resistance to corrosion. Their unrivaled composition makes them a champion solution for industries seeking durable and dependable performance, minimizing downtime and maximizing efficiency in intense heat and challenging environments.

Sample Policy and Secure Shipping

Clients can easily inquire about our sample policy, with asking price details provided on request. Each product is dispatched swiftly via secure shipping channels. We offer FOB Port delivery options, and our typical delivery time is prompt and dependable, ensuring your industrial needs are met efficiently. Safe packaging on wooden pallets or custom solutions further guarantee goods arrive in perfect condition, ready for immediate integration into your process.

FAQs of REFRACTORY SHAPES AND GOODS:

Q: How are the dimensions of REFRACTORY SHAPES AND GOODS customized for specific requirements?

A: Dimensions can be tailored according to customer specifications, ensuring a perfect fit for diverse industrial applications such as furnaces, kilns, and reactors.Q: What is the main benefit of using these refractory goods in industrial settings?

A: These goods offer superb thermal stability and high mechanical strength, resulting in enhanced durability and resistance to corrosion during high-temperature processes.Q: When can clients expect delivery after placing an order?

A: Dispatching typically occurs promptly, with secure shipping practices ensuring delivery within the agreed timeframe, depending on location and quantity requested.Q: Where are these refractory shapes and goods primarily used?

A: They are primarily used in industrial environments, including foundries, refineries, and manufacturing facilities, for lining equipment subjected to extreme temperatures.Q: What is the process for requesting a sample and obtaining the asking price?

A: Clients may contact our sales team to discuss sample policy details and receive the current asking price, with arrangements made for secure shipping and delivery.Q: How do the products material qualities contribute to performance?

A: High-quality refractory ceramics, low Fe2O3 content, and optimal AI2O3 levels result in unrivaled resistance to thermal shock, mechanical stress, and corrosive agents, championing long-term use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Refractory Material Category

Refractory Material

Material : Other, Refractory Material

Shape : Other, Granule

AI2O3(%) : 4045%

Refractoriness : 1790C

Color : Brown

Characteristics : High temperature resistance, superior thermal stability

Refractory Fire Bricks

Material : Clay

Shape : Brick

AI2O3(%) : 35% to 40%

Refractoriness : Above 1700C

Color : Brown

Characteristics : High durability, thermal stability, chemical resistance

We mainly deal in Chandigarh, Delhi, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Uttar Pradesh, Punjab, Rajasthan, Uttarakhand etc.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS